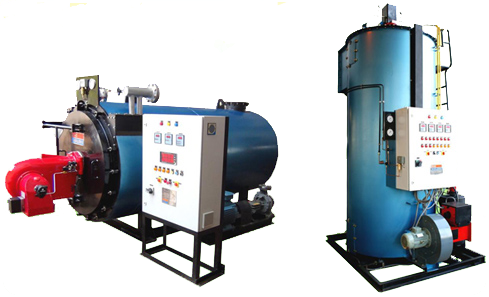

THREE PASS OIL | GAS | DUAL FIRED FULLY AUTOMATIC THERMIC FLUID HEATER

TECHNICAL SPECIFICATION

i - Type – Vertical/Horizontal, 3 pass, Coil Type Thermic Fluid Heater

ii - Capacity – 50000 kcal/hr to 2500000 kcal/hr and above

iii - Temperature - Up to 300°C and above

iv - Fuel - Gas / Diesel/Heavy Oil/ Dual Fuel

v - Thermal Efficiency - 88% + 1% based on N.C.V. of Fuels

vi - Heat Recovery Unit – Economiser (Optional)

vi - Air Preheater - In-built

CONSTRUCTION

i - Vertical / Horizontal Coil type 3 pass Gas / Diesel/Heavy Oil/ Dual Fuel fired Thermic Fluid Heater

ii - Spirally wound heating coil concentrically placed within the assembly formed by outer shell and inner shell

iii - The passage between inner shell and outer shell provided with the Radiator along with the Radiator itself act as a Combustion Air Preheater

iv - Heating coil manufactured out of SEAMLESS PIPE confirming to ASTM – A – 106 Grade B standard

v - Coil hydraulically tested for pressure of 55 kg/cm2 applied for about 30 minutes

vi - Burner components and Air Cone manufactured out of heavy gauge STAINLESS STEEL sheets

vii - Blower provided with statically and dynamically balanced impeller for smooth operation

viii - The control panel is SWITCH GEARED with easy available standard components from market to increase independence

ix - The control panel is WIRED with solid Copper Conductor wires for easy tracing of control circuit adding further independence

OPERATION

i - Fully automatic operation with BURNER ON-OFF modulation for units up to 40 Lac kcal/hr and HIGH-LOW ON-OFF modulation for higher capacity units keeping FUEL CONSUMPTION in proportion with heat demand in the plant

ii - The Burner is pressure atomizing type and is centrally located at the top of the unit

iii - Burner is self igniting and maintains CLEAN and SMOKELESS COMBUSTION all throughout the operation

iv - Preheated combustion Air gives highest Combustion efficiency maintaining high CO2 % and Low Smoke Index

v - Hot Oil circulation pump is of centrifugal type maintaining the circulation of Hot Thermic Fluid through heating coil

vi - A Digital Temperature Controller senses the heat demand in the plant and controls the Burner ON-OFF/HIGH-LOW modulation maintaining minimum fuel consumption

vii - In case of any abnormal operating condition the SAFETIES provided stop the unit and put the same to SAFETY LOCKOUT CONDITION by giving AUDIBLE ALARM and VISUAL INDICATION

SAFETY FEATURES

i - Flame failure device

ii - Thermic Fluid low flow tripping

iii - Overriding temperature tripping

iv - Blow down valve

v - Single phasing prevention cum over load for control circuit

vi - Miniature Circuit Breaker for control circuit

vii - Thermic Fluid level switch on expansion tank (optional)

viii - High stack temperature Annunciation/Alarm (optional)

ix - Fail Safe Instrumentation

x - Control circuit logic ensures Heater going to lock out safety in case of any abnormality in operating condition as well as monitoring instrument failure

COMBUSTION AND HEAT TRANSFER

i - High furnace volume for long furnace residence time ensuring complete combustion of fuel at low excess Air

ii - The Smoke Index is considerably low with low excess Air improving Combustion efficiency

iii - Large radiation surface giving very high heat absorption in furnace with moderate heat flux and heat release rate

iv - Three pass design giving highest total length of passes and longer residence time of flue gases

v - Overall thermal efficiency of 88% on NCV of fuel Oil

vi - The overall thermal efficiency is subject to return Oil temperature from process (minimum return Oil temperature means maximum thermal efficiency)