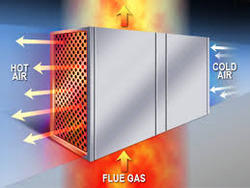

An Air Preheater (APH) is an important Boiler auxiliary which primarily preheats the combustion air for rapid and efficient combustion in the furnace with the primary objective of increasing the thermal efficiency of the process.

The purpose of the air preheater is to recover the waste heat from the outgoing boiler flue gas and transfers the same to the combustion air, which increases the thermal efficiency of the boiler. As every 550 0C drop in flue gas temperature improves the Boiler efficiency by about 2.5%.

Types of Air Preheater

There are two basic types of air preheater

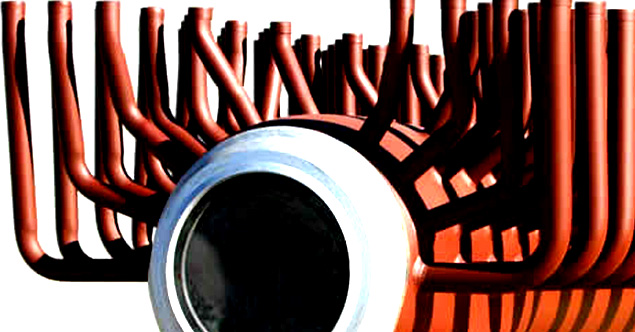

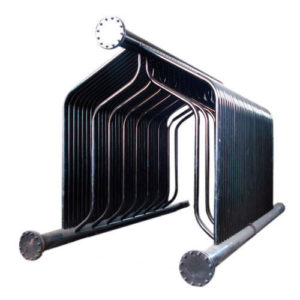

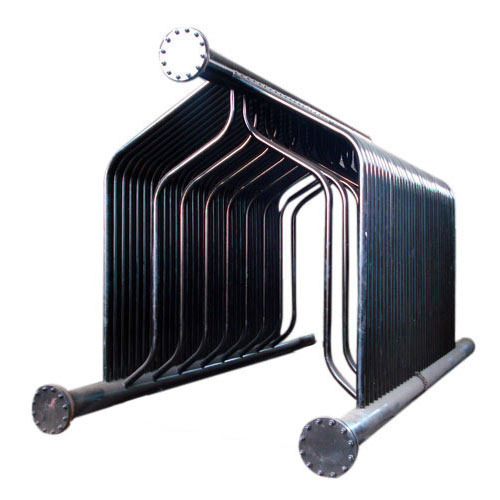

- Recuperative – Tubular type

- Regenerative- Feed water type

Advantages of Air Preheater

- Increases thermal efficiency of the system

- Payback period is very short and increase combustion rate

- Improve and strengthen the combustion

- Reduces the loss of furnace and the exhaust gas temperature, improve the boiler thermal efficiency.

- Air preheater is suitable for all standard fuels

- They are easy for retrofit into existing systems

- These air preheaters are suitable for all waste heat boiler / flue gas boiler / boiler types.

- They strengthen the heat transfer

Disadvantages of Air Preheater

- There are formations of clinkers, on the grate due to higher combustion temperature.

- Natural draught is not possible with air preheater as temperature of flue gases is reduced, also pressure drop take place in the flow of the flue gases. Hence, forced draught is required.

Features at glance

- Large heating surface

- High heat efficiency

- Precise temperature control

- Automatic

- Energy-saving

- Clean combustion