By utilizing our years of experience, we bring forth a qualitative array of ID-FD Fans that is used in boilers, furnaces & various other applications. The offered fan is manufactured utilizing finer quality raw material and most up-to-date technology. Moreover, a squad of our quality regulators performs a string of quality tests on this fan to find out any faultlessness. In line with international benchmark, we provide this fan in assorted customized options and at the most competitive price.

What is a soot blower?

A soot blower is a system for removing the soot that is deposited on the internal furnace tube of a boiler during Combustion, it prevents plugging of the gas passes and maintains boiler efficiency.

Types of soot blowers

- Wall Blowers also known as IRs (Insertable Rotating)

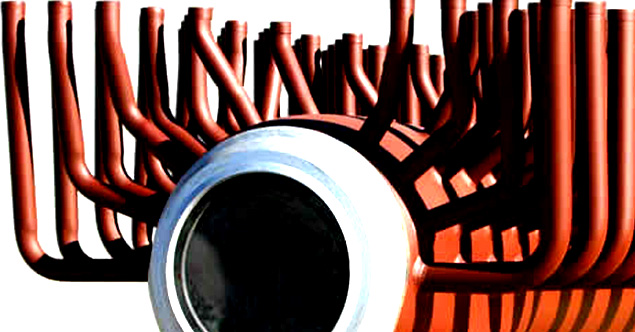

- Long Retractable Soot Blower (LRSB) or IK (Insertable Kinetic)

- Air Heater Blower

- Fixed Rotating

Blowing medium

- Steam

- Air

- High Pressure Water

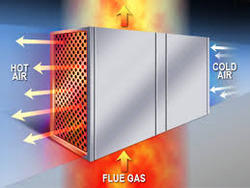

- Dual-media air heater

Manually operated soot blower is normally installed and are limited to shell-type boiler plants and small watertube boilers.

Electrically controlled and remotely operated soot blowers are mostly installed and are an essential feature on large watertube boilers including marine boilers.

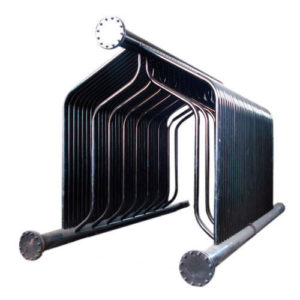

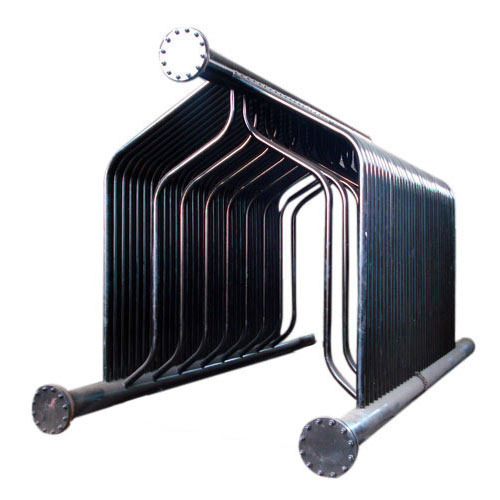

Twin opposing-nozzle type soot blowers with rotation facility, which are fully traversing and retractable when not in use are installed in high-temperature zones, like superheated tube banks and (seldom) in combustion chamber on watertube boilers.

Single or multi-jet soot blowers with lateral movement and non-retractable nozzles are installed in lower-temperature zones.

Multi-jet non-retractable type Stationary or traversing-element soot blowers are installed in the convection tube banks and economizer of watertube boilers.

Causes of Soot Build up

Soot is the inevitable by product of burning fossil fuels, during combustion some mineral constituents and compounds get deposited in a molten or plastic state.

- Ash constituents get deposited on the heat absorbing surface causing slagging and fouling.

- Large amounts of soot can be caused by a dirty, clogged or malfunctioning burner.

- Inadequate draft or low air-to-fuel ratio is a cause for large amount of soot.

- Use of low-grade fuel in oil boilers also produces more soot than.

Soot Prevention and Maintenance

- Regular cleaning of boiler, chimney and flue should prevent soot building up to levels that hinder the boiler’s operation.

- Manual brushing of flue pipe and chimney is the simplest way to clean the system if they are easily accessible.

- Use of suitable special machinery to blow the soot.

- Use of high-quality fuel should lessen the amount of soot.

Soot Puffbacks

Puff-backs are considerably more serious issue than a soot build up. They occur in oil boilers and furnaces, due to excess unburned or partially burned fuel oil which leaks back into the combustion chamber at the end of the cycle and can explode at the beginning of the next cycle causing injury to anyone in the vicinity of the boiler, it also blows a cloud of soot out of the boiler and into the boiler room. If the puff-back is severe, it can damage the boiler and the boiler room.

Causes of Puffbacks

- Leak in the oil supply piping

- Dirty spray nozzle

- Boiler shutdown problems and poor maintenance

Prevention of Puffbacks

- Regularly cleaned and well-maintained boiler is the best way to avoid puff-backs, but they can still occur.

- Contact a technician and avoid running your boiler until the problem has been fixed.

Advantages Of Soot Blowers

- Increases the boiler thermal efficiency by 5% to 10%.

- Prevents the blockage and plugging of gas passages in the boiler

- Maintains flue gas temperatures within design conditions at key locations

- Soot blower used with temperature controlled mode increases overall efficiency by 2% to3%

- The effectiveness of cleaning around the superheaters & economiser

- Low operating and maintenance cost.

- Supports the optimum operation of air emissions control equipment

- Reduces the risk of soot fires